Farewell

to Kangaroo Valley Historic Railway

Last

weekend, I drove to Yass, to participate in the final operating session on

Stephe Jitt’s “Kangaroo Valley Historic Railway”. After this session, the layout is being

dismantled, and faces an uncertain future, as Stephe’s property, “Old Linton”

has been sold

|

| Old Linton homestead was originally built in 1857. It has had a long, and chequered life, with expansion, and improvements - just like KVHR |

My

involvement with the layout dates from the 1990s. Stephe approached the ACT Model Railway Society,

with an offer of an exhibition layout for the upcoming Malkara Model Railway

exhibition.

At that stage,

I was on the Malkara exhibition committee, and took it upon myself to inspect

the layout. I liked what I saw, and the

layout was duly exhibited. Stephe later

joined the ACTMRS, and regularly offered Kangaroo Valley as the stand-in club layout for

other exhibitions, which allowed the members of the society to run Australian trains,

in an Australian setting.

Those who know

me understand that I tend to look at possibilities, and possible improvements

of any model. Kangaroo Valley as originally

built, had some awkward crossover trackwork, and operation of the mine branch,

seriously impeded the running of the main line.

Maybe I was a bit too convincing, as Stephe took on some of my suggestions, and the 3 way point, and

double slip were installed, and the platform 3 dead-end track was extended to

the holding yard.

|

| The town of Kangaroo - on the original two modules. |

Stephe later

added a meatworks and leather tanning industry to the front on a new section,

whilst vastly increasing the “fiddleyard” at the rear.

|

| Meatworks, and ice plant. The backscene was painted by the same artist who painted the original backscene behind the Kangaroo town modules |

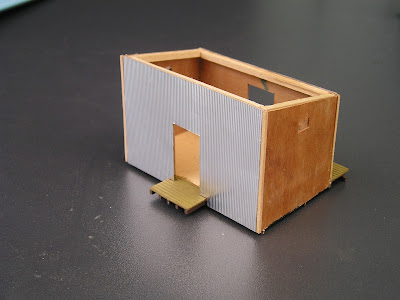

My last

enhancement to the layout, was to add 4 buildings to the Kangaroo township, to

give the town more of a Bundanoon feel. Well

that was my excuse to contribute something of my own to the layout

For those

with copies of Australian Model Railway magazine, Stephe wrote an article on Kangaroo

Valley Historic Railway, which appeared

in Issue 292, Feb 2012.

AMRM No. 292 February 2012

Kangaroo

Valley

Volume 25, issue 292, page 16.

Type: Model Railway Layout

Author: Stephe Jitts

Published: 01/02/2012

After the

article was written, Kangaroo Valley Historic Railway was totally transformed from

an exhibition layout, into a permanent home – being the former hay loft of Old

Linton. Stephe quickly filled the space

of the loft with more track, and incorporated Kangaroo Valley as just a town

within a much larger east coast mainline stretching from Sydney to Eden (and

beyond in staging).

Stephe liked

to share his layout, and regular once a month operating sessions were firmly

placed on the calendar. Although, the

Covid situation this last 2 years has not helped, I only got to the occasional session – I was

often tied up with dog-show duties, the 2 hrs there, and 2 hrs back, plus the

expense of fuel were not conducive to a more frequent attendance. Probably my loss. But it does give me a lesson, that I may not

get operators for my future Wagga layout.

‘Build it and they will come’ is

a not always a good recipe for success For the last session on KV, too many

operators was the problem, and the sessions were split into 4 x 90 minute

blocks, with some operators able to leave, and be replaced with newly arrived

operators.

“Old Linton”

homestead was recently sold, after being on the market for many years. It was the subject of a feature “Selling

Homes Australia” television program a few years back. I don’t think Stephe thought it would sell,

as Kangaroo Valley Historic Railway steadily grew into it’s new home – and scenery,

and electronics kept improving, and evolving.

My record of its growth has been

a bit patchy, and disappointingly, I

forgot to pack my proper camera to record this last melancholy event. But I did have my phone camera, which I hope

will show some of the improvements that have occurred over the years

|

| Tannery is another industry associated with the meatworks. I was very interested to see this, as my future Wagga layout will also have a tannery at Bomen |

|

| Engine facilities at Kangaroo Valley are small, but cover all the basics. Stephe uses LENZ DCC, which takes some getting used to. Many of the points(turnouts) are DCC controlled, although Kangaroo Valley has a dedicated signalbox operator, and shunter, that assists in making, and breaking up trains. |

|

| A long aisle now separates Adamtown from KV. This picture taken a few years ago. The operators on the left are working Sydney, and Eden fiddleyard. Unfortunately, I don't have pictures of the yards, but there is a good picture of Stephe working the earlier incarnation of the fiddleyard in AMRM |

|

| Looking the other way towards an industrial area, Adamstown has developed scenically, now has catenary, and Kangaroo Valley operations now has an electric commuter train that runs from Sydney Yard, to Voilet |

|

| Gasworks at the end of the Adamstown aisle. Picture taken before the catenary installed on the mainline |

|

| A warehouse, on the gasworks siding. This is a recycled building that I built for the ACT Model Railway society from a Heljan Bank building kit in around 1987. Stephe had no idea of the history when he obtained the building from the ACTMRS when they were clearing out their old EHO guards van. I am glad it found a new home |

|

| After Adamstown aisle, the tracks disappear around the entrance door, and reappear in another industrial area, this one of a port scene. This area was a future scenery project |

|

| Voilet was the end of the catenary. It was also the junction for a small industrial branch to Limestone. The Limestone local is awaiting the signal prior to departure to Kangaroo Valley. |

|

| Basic Scenery for Limestone in this early picture. The carriage shed is used to stable the CCA carriage |

|

| More scenery has been added in this later picture. The 13 class appears to be the main motove power. Stephe had fitted a very good keep-alive in this loco, and is most reliable |

|

My phone camera picture from last weekend shows ballasting complete. The line extends to the right of this picture to a limestone quarry - a source of revenue for the railway

|

|

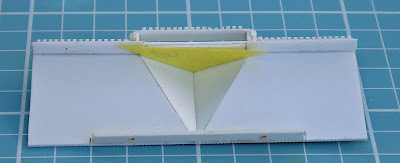

| From Voilet, the line passes over a river on a 159 foot Whitton Truss bridge. The trackwork here is gauntlet |

|

| Scenery makes the difference |

|

After the bridge, the line runs to the Cement works. This is the destination of the Limestone Ballast train. Note the structure above the tunnel. This is part of the original exhibition layout - the destination of the coal branch out of Kangaroo Valley.

|

|

| This is what the section from Limestone to Cement works looks like. The limestone quarry is above the mainline tunnel on the right - Voilet and the river bridge are in the distance, and the cement works on the Left, just out of view |

|

| Another branchline connects to the mainline at Kangaroo Valley. This one disappears behind the meatworks, only to skirt the walls and emerge on a new deck on the other side of the hay loft room. This is the station of Ethyl, on the "Alabmob" branch |

|

| Alabmob is the site of a milk factory. Always a good source of revenue |

|

| Alabmob station in the plywood central days, before scenery |

|

| With more scenery. My poor phone camera however shows the waybill pockets as part of the operation. Eagle eyes will also notice that the station building has been replaced, and relocated across the tracks. Changes were a feature of this layout over the years |

|

| The mainline headed south out of Kangaroo Valley, and beneath Ethyl, and the Alabmob branch, had more of an industrial feel. These were only recent additions. |

|

| The meatworks needed a saleyards. This had a long siding small connection from the Meatworks near Kangaroo valley. Below this area, there was hidden staging for the "melbourne" connection out of the Eden fiddleyards |

What is in the future. As Stephe said in his AMRM article, “Crystal balls are difficult to read, and if I have learnt anything in the last twelve years, it is that change is constant”.

Stephe hopes that KV will rise again in a new location, probably a larger shed, which will address some of the hay loft constraints, particularly the access, and aisle width.

|

| Stephe's workshop, and stairway(ladder) to the layout in the hay loft |

|

| The layout upstairs made everything worthwhile - but we are not getting any younger, and entrances such as this are best avoided |

|

| A final look at Kangaroo - with a historic set of trains. |

Until next time.