Roofing

Wagga station - 1

|

| Western end of Wagga Wagga station. |

|

| Looking east. Picture taken from the footbridge |

|

| Picture of Wagga station from above. Note the positioning of the chimneys and the size of the satellite buildings. The mainline has been resleepered with concrete, where the platform loop still has wooden sleepers |

After the

last blog post, I looked at the prototype photos of the roof, and noticed that

the trim above the corbels was thicker than the trim on the triangle

sections. So before I did anything, I

added some additional styrene strips to bulk this area up to match photographs.

|

| Pegs make a convenient clamp for the extra styrene. |

I had also

thought about guttering. All of the

gutters I had added on my structures up to now, were simply 1.5mm angle styrene strip. Whilst this works,

it is mechanically weak. The Wagga

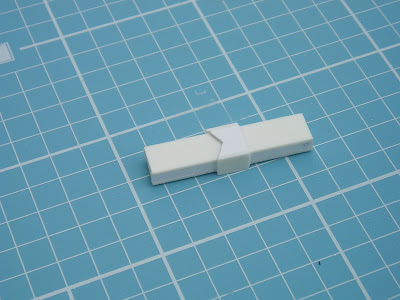

station allowed me to experiment with an alternative, which the below diagram

attempts to show

|

| The angled corrugated styrene rests on the gutter strip |

The 0.010 x

0.250 styrene strip was added on top all around

the station walls (but not on the triangle sections). Some 0.010 x 0.040

strip was added to form the guttering in a few places to check out my idea.

|

| The guttering is a prominent detail. I have tried to smooth the join between the two sections of styrene above the corbels - although the camera shows that I was not totally successful in this task |

|

| Guttering detail from above |

.I thought

reinstatement of the North-south triangle sections of roof would be a good

first start. I made up the triangle

pieces for the platform wall sections.

After careful measurements, I then fabricated 8 more internal triangle

sections (4 on each side). These

triangle sections rest on the guttering 0.010 x 0.250 strip, but leave enough

of a gap between the future corrugated iron styrene and the guttering 0.010 x

0.040 strip. A number of solid beams

were then cut, to join the lot together

|

| The North-South roof section fits between the triangle wall details. The smaller intermediate triangle sections were sized to fit on the wide gutter strip as show in the diagram earlier. The notches in these triangles were cut out with my nibbling tool. This selection of parts is the first group of two needed |

|

| My nibbling tool is a much used tool. I bought my first one at Tandy (remember that electronics store?), but after it wore out from overuse, a replacement obtained from Jaycar. Extremely useful for cutting squares in styrene, and thinner sheet brass |

The

nibbling tool cut a channel into the styrene that was almost exactly 0.080”

deep certainly matched my 0.080 x 0.188 styrene strip (the size I also used to bulk up the walls above the corbels).

These parts

were then fitted in situ on the station.

There is no room for sloppiness here – the roof has to fit snuggly, and

the end triangles key the roof into the correct position. I allowed 24 hrs for the glue to fully harden

|

| Juggling all the angles to get everything square needed a lot of luck, and perserverance. I used two types of Tamiya styrene cement - one was thicker, and allowed for minor repositioning prior to setting - the other type was instant fix. |

|

| After the joints had dried, the assembly was removed from the station, for measuring up. Note the rebate in the end triangle areas for the snug fitting of the corrugated styrene. |

Adding the

corrugated iron was next. To save

material, I didn’t run the full width with the corrugated styrene. To do so, would have prevented a neat join

with the east/west set of roofing iron.

The heavy styrene beams hold the shape well.

|

| The corrugated sytrene was cut into 4 sections, and was glued to the beams, and end triangles whilst attached to the station. The effect with the guttering is just visible. |

So far, I

am pleased with the effect. However, It

is just the first step. There is still a

lot more roof to add. I have not yet

decided if the entire roof will be one section, or if I will have the center

section removeable (Which may give me a change to have a detailed interior waiting

room). Then there is the matter of

securing the roof to the walls (screwing is the thought) – plus the chimneys.

===============

I am still

getting used to the new google blog interface

No longer can I preload all my pictures, and select the ones that I want

for insertion in the text. But it does

give better stats. I noticed that my

blog-post on oil depots has now passed 1000 views. It is 350 views ahead of my next most popular

post on the Auscision RUB set. Maybe

these are things people search for in Google?

Trust you have found something of interest in my roof construction approach, particularly with the guttering. Until next

time.