Detailing on Wagga Wagga station - continues

Detailing is something that takes ages, but is necessary to complete a wagon, loco, or structure. With a modern kit, most of the detailing is included. Some of the older "craftsman kits" rely on the skill of the modelmaker. Scratchbuilding, may give an opportunity to purchase parts to suit. I may have taken on a bit more, as modelling an iconic structure, means that many of the details have to be fabricated from raw material.

|

| The Tumbarumba bound railmotor awaits departure from Wagga station, around 10am. This picture taken on the Wagga station diorama with real sunlight, and shows some of the detailing applied recently |

Fly Screens on Parcel Office windows

|

| Out-of, Parcel Office, or Museum building |

|

| Ultra fine mesh cloth was coloured with permanent felt tip whiteboard pen. |

|

| The window frames and bars were made from styrene strip directly onto clear plastic |

|

| Check for fit.. |

|

| More details made. I had taken some close-ups of the the two air conditioners to try and get them right. |

|

| Doors and downpipes |

Platform and platform road

|

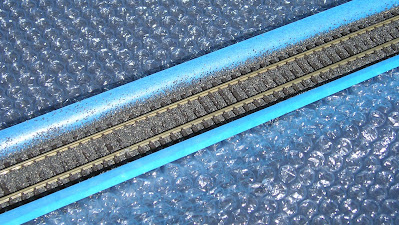

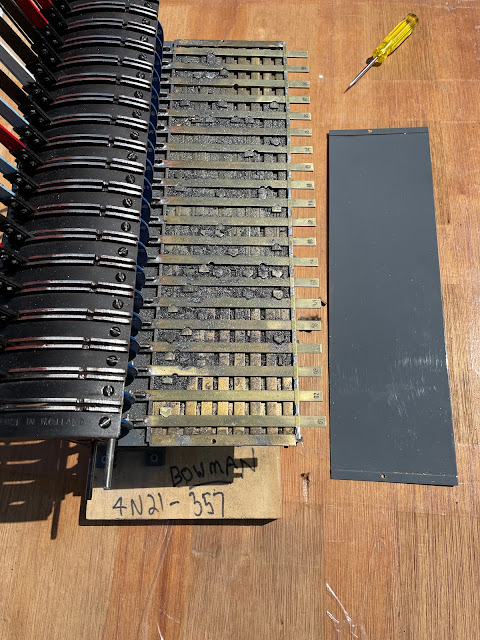

| Ballasting done in the normal way - with the masking tape to prevent unwanted spillages. The bubblewrap was just in case the glue ran onto the support table. |

|

| Wagga station in the late afternoon, picture taken from the footbridge (shadow) |

|

| The parcel office from the roadside. The downpipe on the main station toilet extension is visible |

|

| The main toilet block has an unusual window style. I had assumed the horizontal "bars" were shutters, but closer inspection, the bars are actually metal bars, with a wooden blind behind. |

|

| Both roadside, and platform side windows made from strip and rod styrene on 0.020 styrene sheet, backed onto clear styrene "glass". I won't kid you, these took ages to make, |

|

| The bars are difficult to see in this platform side angle (the roadside image at the front of the blogpost, shows them better) Platform brickwork not yet weathered |

At what point do I stop this process? A lot of years have passed since I was given some advice. "Twelfth Street Yard", the American layout for the ACT Model Railway Society had been on the exhibition scene for about 5 years, yet I continued to champion adding more and more details, as my thinking at the time, was that the viewing public needed to be rewarded the closer they looked. Then, my view was countered. The person said that '12th Street' was already detailed enough, and I would be better spending effort on a new layout. And they were correct. The ACT model railway society had 2 other layouts, and I moved towards detailing, and improving "Little Austria", a module HOe layout. "Yendys" was at that stage, started, but not actively being worked on.

I am close to reaching the sufficient "detailing" for Wagga station. Yes, there are a few more downpipes to add, small signs to make, lamps, and positioning seats, litter bins, & passengers. I know there is more that could be done, like a waiting room interior. However, to continue with Wagga would delay other projects that I am itching to progress and share...

-----

Times are changing. It is important to record now, what might change tomorrow. Some examples

Edmonston Street Bridge

|

| I took these pictures in September (and this bridge was the subject of an earlier blog-post) |

Harefield Shuttle

One of the regular trains that I watched (and listened too) was the Visy Harefield shuttle. Their normal motive power was vintage Goodwin Alco engines - and the burble from their engines was quite distinctive from the GM, GE, and chinese built locos.

Well, Visy relocated their intermodal operation from Harefield to Bomen's new intermodel facility on Nov 24, 2022. This reduces the round trip truck haulage from the Visy factory in Tumut by about 30km, and allows Visy to run heavier trucks. The Bomen operation also means that complete trains can now run direct to and from Bomen, and the breakup of trains at Junee for the shorter Harefield siding is also not required. The Alcos are still running light from Junee, to Bomen, as they are needed with shunting at Bomen.

I failed to take enough pictures, but there are u-tube videos of the shuttle in its heyday.

|

| In 2018, the shuttle departs Harefield (silo in background) in the gloom of the late afternoon. Alco smoke a feature. As a passenger in the car, I wasn't able to stop. |

Finally

If I don't write another blog post in the meantime, may you all be safe for the upcoming Holiday period, and hope that you are able to get some quality time.

-signals-diagram.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)