Bomen Signal box Interlocking - or - who is going cranky

When I was designing the future Wagga layout, I had

anticipated incorporating my partially built 56 lever frame only for the Wagga

station. The station at Bomen though

didn’t seem that important in the scheme of things, and I was not going to

worry about this until the layout was constructed.

As it turns out, I have not as-yet been successful in

finding a builder, who is willing to undertake construction of my train

room. So, projects that were on the back

burner have advanced instead.

|

| My picture of Bomen was after the signal box removal in 1983 |

Prototype Bomen

Bomen was a crossing loop, with some additional

sidings. Only the sidings for the

meatworks stock yards were interlocked by the frame, the long siding into the

meatworks, the siding into the canning factory, and the one for the leather

works were on a simple ground throwover levers on the yard tracks

Bomen’s signalbox according to Bob Taafe’s signalbox book,

was relocated from Uranquinty around 1941.

It was situated on the southern side of the station. The frame was 20 levers.

|

| A picture from the internet - showing the signal box |

Modelling.

Way back in 1982/3, the British magazine “Model Railway

Constructor” ran a comprehensive monthly series authored by Martin Goodall, on

constructing a layout based on the GWR station of Bodmin. Parts 15 through 23 concentrated on signals,

and interlocking. Inspirational, as well

as informative. The parts dealing with

mechanical interlocking were the best I have ever seen on the subject, and from

the time I read the article, I took an

intense interest in this obscure aspect of modelling.

(copies of the articles are at the end of this blogpost)

Unfortunately, this interest started just after the NSW

railways removed the signalboxes at Wagga, and Bomen in 1983.

But, luck was on my side.

A fellow modeller, who had also seen the MRC articles, had actually

started making interlocking machines in approx. 1/10 scale, using the

principles of the MRC articles. Then around

1990, the Defence department moved him to Queanbeyan, where I was living, and I

got to know Tony. Tony Kociuba’s layout

Manuka, was featured in AMRM way back in issue 188 (October 1994). I got

to work a fully interlocked lever frame at his home, and at exhibitions. After a while, Tony trusted me to build a

large lever frame under instruction and guidance, that being the 56 lever frame

of Wagga Wagga .

|

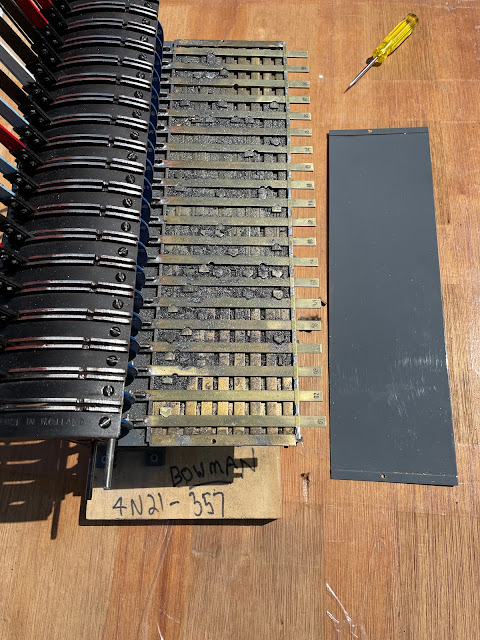

| The Wagga signalbox frame was built by me in the 1990s - still needing to be interlocked. |

Since moving to Junee, Tony and myself have maintained a

sporadic contact. When Tony found out

about my plans for the layout, he volunteered to construct Bomen’s frame as a

contract build for his Mackenzie in HOLland hobby business. I supplied Tony with as much information I

had at the time unfortunately, with the

lousy small pixel signal diagram picture.

It was also a bit of a fiddle, as my rendition of Bomen’s track plan is

mirror image of the original. Tony now lives in Bendigo, and detoured into

NSW via Junee to show me progress, and later the finished lever frame – fully

interlocked.

|

| Tony made 2 visits - the first one showed me the progress of the frame, prior to interlocking |

Now I have to learn the frame, and crunch the levers in the correct order to free up the mechanism Excess force will break something, so you don't want to pull the levers in the incorrect order. It will be a challenge for the future Bomen operator too, but learning the frame was part of the real signalman's job - and simulating this on a model takes things to another level of realism

.

|

| Albury to Junee. The levers have to be pulled in the pull chart order as seen on the signal box diagram. |

|

| Albury to Platform road |

|

| Junee to Albury |

Integration into the layout will be via electrical

connections, rather than through a mechanical links direct off the levers

Signals will of course have to be built.

|

| Trouble cat - gives an idea of how big the lever frame is. She may not yet be the station cat, but takes a lot of interest in what I am doing |

Observation. A

lot of older magazines contain a wealth of information. Some of these publications get converted to a

digital format, but a few never do. It

saddens me to see the wisdom of these now forgotten publications, consigned to

landfill, or recycling. Please, consider

the process that brought the articles contained within to print. The author, the editor and their desire to

not only sell magazines, but the sharing of knowledge. We are all better modellers by learning from

their experience

-signals-diagram.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)