Wagga Wagga Station Roof progress

It probably goes without comment, but the complexity of scratchbuilding doesn't rise in a linear fashion, with the larger the project - it is more like exponential. Errors in measurements made at the beginning don't show up until much later, when something doesn't work, or look quite right.

|

| Wagga station was refurbished, and repainted in 2017. The concrete rendering over the brickwork had been removed above the awning, giving a clue to the original construction in the 1870s. |

At 53cm wide, I am rapidly using up my supply of corrugated styrene sheet, so it is important to minimise the wasteage. I should have included this on my last blog post. Below is how I cut the styrene for gable roofs

|

| rearranged. |

The western wing roof was built in much the same way

Roof details.

When people view your structures on your model railway, I suspect that the first thing they see is the roof. So it makes sense to detail it.

|

| Another view during the refurbishment showing the eastern wing |

On the above picture, you will notice the two chimneys, and the roof vent. Sizes of these, as viewed from the ground are not obvious. So I did some measurements from the elevation plan I had, and scaled it up to HO.

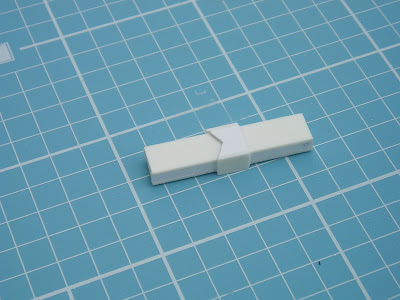

First was the roof vent. Before I started cutting into my ever dwindling corrugated styrene sheets, I drew a diagram, and made a plain styrene vent to check the fit, and size. Little bit of trigonometry helps with the angles

|

| Roof vent drawing. All dimensions in mm, not what I scribbled. I drew the plan 5 times larger than scale HO |

|

| Roof vent mockup in the right position |

Next was the chimney. Wagga station has 4 chimneys, 2 are the same, the others vary slightly. First, draw a diagram

|

| I had to guess one of the dimensions from photos. |

|

| The first stage of construction was to build an inner tube from 4 pieces of styrene. The wide base above the roof line actually happens a bit later |

|

| Cut a hole in the roof to suit the tube. |

|

| Insert the tube into the roof. The construction of the trusses of the roof can be seen from this view |

Next stages are to complete the 4 chimneys, 5 roof vents, the platform gable roof edges, the ridge capping, the rest of the guttering, and downpipes. Then the two "extensions" that are visible in the 2 prototype pictures in this blog post. Painting is then probably going to happen, prior to the awnings and verandas being installed.

Still managing my new-years resolution for at least 30 minutes a day on the workbench. Although I had really hoped to have finished the Wagga building well before now. Until next time.

keep pushing on Rob your doing more than me you will get there

ReplyDeleteThanks For sharing this Superb article.I use this Article to show my assignment in college.it is useful For me Great Work. top roofing contractor md

ReplyDeleteThankyou for your kind words. Good luck with your college education. I have found that making mistakes, and learning from them, is the key. This design has come about through an evolution process of many earlier techniques. Fortunately, my mistakes only cost me time and material, and I won't be sued if my roofs fall down :-)

ReplyDelete