Modelling challenges

Yesterday, whilst I was at the workbench, a storm brewed up to the west of Junee, and was about to make its presence known. It hit my place around 1pm, but as I discovered later, my place got off lightly, with just broken tree branches, and upturned pots on the veranda.

|

| The Junee Roundhouse lost part of its roof in the Nov 28th, 2020 storm |

It is often said, that when one builds a model, to show off the interior, one should make the roof removable. But I don't think this is what they meant

|

The roofing iron from Bay 7 is drapped over the exhaust vent of bay 8

|

|

A wide angle of the previous shot. Quite a number of Graincorp 48 class engines are stored in the open. The Graincorp 48214, previously 48148 shows evidence of the poor standard of the latest paint

|

|

Roofing iron from Bay 15, 16 or 17 were blown towards the east, and landed on the stored 48/830 engines. This and the below 2 pictures were taken off the Junee Community facebook pages, The iron had been removed by the time I took my pictures.

|

|

| Probably the brightest "inside" view of the roundhouse I have seen. |

|

48 class locos being refurbished/serviced in anticipation of the bumper harvest. The roofing iron over bays 5 and 7 had been peeled back. It is possible that this iron was originally installed in 1947 when the roundhouse was built.

|

==========

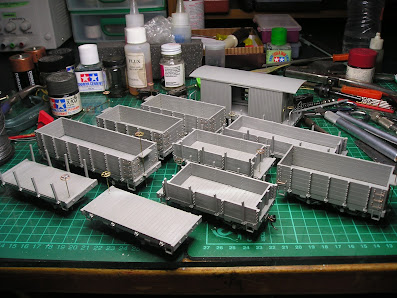

Anyway, back to the Wagga Wagga station build. As I mentioned on my last blog post, I am recovering from a nasty leg infection. As a result, I can only spend at most an hour at the workbench, before I need to have a break, and rest my still partially swollen leg. The upside, is that I am trying to get two or three sessions in per day, in the morning, after lunch, and around 7:30pm. Progress is now steady.

|

| The main entrance wall has been fleshed out. I try and make small improvements to my process. The doorway on the RHS has had the arch detail installed, and by using the 0.040 styrene below as the guide to "hollowing" it out, I saved a bit of time over the previous brass pattern method. Once the arch is formed, then the door insert will be added - result looks like the door on the LHS |

|

| Marking out the parts was a matter of using my field measurements, converting them with a calculator to 1/87, and drawing them directly on the styrene. I even broke out my high school tech drawing compass for the arches over the windows |

|

| One of the windows on the LHS veranda. |

|

| The LHS Veranda has 3 sets of windows. It is effectively a mirror image of the RHS veranda |

|

After some more detailing, the pair of wings looked like this. RHS on top, LHS on bottom

|

|

A washed out image due to the sunlight, and the dark background, but 5 sections routhly positioned to show the main station size.

|

|

| Further detailing on the LHS wing. The plastic count of parts of just this wing is 233. It is important when building walls to get as much detail on them whilst they are flat on the workbench, because once they have been assembled into a 3D structure, things become more awkward, and the structure is subject to damage. The main Wagga station is around 550mm in width, not counting the small extensions at the ends, that will be made later. |

I will not kid you in saying that this build is straight forward. Just from a time factor. Already, there are some (hopefully) minor errors that will be difficult to correct. I may fill you in later with these, but the upshot is, I have enough building left without worrying too much to rework to get things 100%. I will learn from the experience should I ever have to build another model of this complexity.

But, I have to get over to Wagga again, and take detail shots, and measurements of the platform side wall. My current batch of pictures was taken from Railway Street, and whilst probably OK, as this side will be hidden from viewing when the station is planted on the layout, I would like to get it right. I was told the best time to view is after the departure of the Melbourne bound XPT.

Until next time, stay out of the wind.