The

Southern Aurora train

The

Southern Aurora was a first class premium sleeper only service, that ran

between Sydney and Melbourne. The

service started on April 16th, 1962, and due to various reasons, finished in August 1986.

The Aurora

was scheduled as an overnight train, running daily. One train headed north from Melbourne’s Swanson Street

station (now Southern Cross), and the southbound train left Sydney Central. They crossed generally north of Junee on the

double track.

Both trains

were not timetabled to stop at Wagga Wagga, so I never got to ride on

them. For Wagga passengers wanting an

overnight service, the railways provided the Spirit Of Progress, a train I got

to ride frequently in the late 1970s, and 1980

The

Southern Aurora was always diesel hauled.

|

| PHN power van attached to train #66, (not the Southern Aurora), heading north, has just passed the Urana Street Level Crossing. Picture by Tony McIlwain Dec 13, 1961 |

|

| Southtbound and late running Southern Aurora running extra late, and stopped as someone had dropped the staff which needed to be found. Sept 13th, 1962. Three pictures by Tony McIlwain |

Carriages

used.

Both NSW,

and Victoria co-operated on the building of the stainless steel carriages, which

are modified Pullman designs (for the loading gauge differences between

Australia, and USA) There were 7 main

designs

PHN Power

Van. 6 were built initially,

with one additional Power van in 1970 (after Violet Town accident destroyed PHN

2370)

MHN Parcel vans 3 were constructed

BCS Lounge

cars 3 were initially

constructed, with one replacement in 1970 to replace BCS 2355, destroyed in

Voilet Town accident in Feb 1969)

RMS Dining

cars 3 were constructed

DAM

sleeping car These are deluxe

twinnette. 2 were constructed

NAM

sleeping car Twinette. 9 were

constructed for the Aurora service, 2 as

late as 1971 to replace Voilet Town destroyed NAM 2339, and NAM 2343. (Note 5

additional NAMs were built from 1959, and used on the Brisbane Limited,

and 3 were used on the Spirit Of Progress)

LAN

sleeping car Roomette cars,

with a curving corridor. 11 constructed

– three in 1970 and 1971 to replace those destroyed at Voilet town (numbers

2345, 2346 & 2350). (Note 6 additional LAMs were built from 1959, and

used on the Brisbane Limited)

(Thanks to

Ian Black for much of the above information, the rest from Wiki)

When the

Southern Aurora train ceased, were the carriages scrapped?

Fortunately,

most of the carriage fleet was sold, or donated to various groups, and

museums. It is still possible to see,

and ride on them.

|

| A preserved Southern Aurora passed through Wagga in 2012. (picture from the internet) |

Modelling

the Aurora carriages.

Ignoring

the earlier out of scale, and generic stainless steel corrugated carriages

produced by Triang/Hornby, Lima produced models of both the Indian Pacific, and

Southern Aurora sleeping cars in the 1970s.

The Southern Aurora cars were different from the Indian Pacific, in the

design of the sides, but otherwise they used the same roof, and carriage ends. These models were made in quantity, to go in their trainsets, along with NSW diesel

4469, or their horrid VR S variant,

which I will say no more). The carriage

was a fairly basic model, but a train of these did capture the feel of the

Aurora. However, being a basic model, the carriages were

lacking details. Casula Hobbies sold me

an underframe kit, which improved the look, by adding battery boxes, airtanks

and clutter. Replacement of the couplers

finished my improvements. Other simple

upgrades were replacement RP25/110 wheels/axle (to replace the Lima cookie

cutter wheels), and I undertand there was a flushglaze window kit.

|

| Lima Aurora carriage, with underframe fitted. Similar to the NAM sleeper in the window style. The "railways of australia" decal is obviously a hangover from the Indian Pacific |

|

| The underframe was a single piece of cast resin, glued or screwed to the base of the coach |

Modelling

the aurora train with Lima coaches was not that convincing for the purist, in

that Lima didn’t include the dining, lounge, or parcel vans. Lima later did introduce a power car for the

Indian Pacific, although that again used the same roof as the coaches, and none

of the exhaust openings. Both Hanovale

Models, and Hawksmoor produced kits for specific coaches for the Aurora. I bought the Hawksmoor PHN power van, but

have not assembled it

|

| The Hawksmoor PHN kit included flush windows, bogies, and cost me $81. Being a resin casting, the sides have bowed slightly |

Some other

modellers went much further. Ian Black’s

series of Lima improvements, finally appeared in a series of articles starting

with issue 294 (June 2012) in the Australian Model Railway Magazine (AMRM) on

modifying the Lima cars to make up an entire Aurora train. For the dedicated kitbasher, these articles

are highly recommended for the techniques, and ideas employed. Ian has recently authored a small 36 page booklet on the aurora cars, available from the normal outlets. I don't have this book, but based on other modelling books Ian has authored, that I do have, it is recommended

In 2010,

TrainBuilder, a Victorian based company, sold a limited number of Aurora sets ,

made in China, RTR in brass. Their sets

of 7 coaches (DAM, NAM, LAN, PHN, BCS, RMS, & MHN) were priced at $3800, with individual extra

sleeping carriages around $550 each. I

am not aware if this set has been rerun

Then in

2016, Auscision brought out a 10 car Southern Aurora set, in RTR plastic for

$1400, (sets with an additional $100 for a period specific lit “Southern

Aurora” sign on the parcel van, and power cars were also available). These sets sold out quickly, and I was happy

to secure one set. Auscision’s rerun of these

sets in 2023, and at time of writing, are still available. Cost now $1500 ( or $1600

with the sign)

Neither the

Train Builder, or Auscision sets have been reviewed in AMRM. Thus an opportunity exists to do another

quick review

Picture

review of Train Builder Aurora set

I recently

was successful through an online auction of obtaining a Train Builder Southern

aurora 10 car set. On receipt of the

set, there were 2 RMS dining cars, and no MHN parcel van. The previous owner had also replaced the

brass Train Builder bogies, with Auscsion bogies for better running qualities. Trainbuilder have fitted lighting to all coaches, and a switch underneath can turn it on or off. This only works with the brass bogies (that I don't have). I didn't weigh the coaches, but they are more weighty than the Auscision set

Note. Click on an image for a bigger view. The pipework on these coaches is very impressive, and the thumbnail image doesn't do it justice

BCS Lounge Car by Trainbuilder

RMS dining car by Trainbuilder

.jpg) |

| The dining car was the only carriage in the Trainbuilder set that has an interior. |

Picture

review of Auscision Aurora set.

|

| The Auscision box is impressive |

|

| The coaches are neatly presented. Note. I have taken away the upper sheet of protective packing |

All the coaches, dining, and lounge car are fitted with full interiors. The blinds on the windows are particularly fine, and make it extremely hard to see inside the sleeping cars. The end diaphrams are flexible, and better than Train builders (in my opinion) Auscision have made the decision to not model the DAM sleeper. Auscision couplers are Kadee and designed for radius greater than 24". Alternate couplers are provided for tighter radius curves (if needed). End lighting for the PHN, and MHN end cars is provided, with a 21 pin DCC socket for specific control of these. Weight of the coaches is consistant between classes - being between 145 and 149 grams

Auscision BCS

Auscision PHN

Auscision RMS

Auscision LAM

Auscision NAM

Auscision MHN

Conclusion

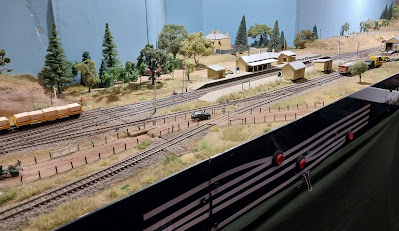

Both TrainBuilder, and Auscision have done justice to this train. As you can see from my pictures, there is little to tell them apart. Once I add

the locos, the Southern Aurora will constitute quite an investment for a pair

of trains that on my layout will run from one staging yard, to the other,

without even stopping at Wagga Wagga. They say modellers can be crazy, but at

least I got to write them up in my blog, and share some really great prototype pictures, courtesy of Tony McIlwain.

Until next

time, build a model or two

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)